Beyond lithium-ion batteries, the next big thing

Sodium-ion batteries will bring power to electric cars, industrial vehicles, solar PV projects, and 5G telecom. Is 2023 the breakout year? A look at the latest commercial and research trends.

Today’s electronic devices rely on lithium-ion batteries for power. But is enough lithium available from existing and planned mines to meet consumer demand? The answer is found in the commodity’s market price.

Why move away from lithium? Prices are surging.

Lithium-ion batteries are ubiquitous because they store high energy levels and charge quickly. And high-energy batteries are best for electric vehicles (EVs). For example, a Tesla Model Y can travel 330 miles fully charged and refill in 15 minutes — the time it takes for a coffee break — for another 200 miles at a Supercharger rest stop. In addition, newer lithium chemistries are adding higher energy densities for trucks and performance cars. Since 2008, energy density has increased by more than 800%.

EVs are gaining popularity, doubling sales from 2020 to 2021. This growth means global EV sales have gone from just over 3 million units in 2020 to about 6.5 million units in 2021. According to BloombergNEF, more than 20 million passenger car EVs, 1.3 million commercial EV vans and trucks, and 280 million electric mopeds are now powered by lithium-ion batteries.

More importantly, EV sales have passed the tipping point for consumer adoption. Bloomberg puts the inflection point from a niche, low-volume sales product to a fast-selling product at 5% market adoption. For EV sales, Bloomberg notes:

For the past six months, the US joined Europe and China — collectively the three largest car markets — in moving beyond the 5% tipping point. If the US follows the trend established by 18 countries that came before it, a quarter of new car sales could be electric by the end of 2025. That would be a year or two ahead of most major forecasts. — Bloomberg July 9, 2022, in Hyperdrive

States and federal tax incentives will spur even faster EV sales. For example, the Inflation Reduction Act (IRA) reinvigorates expired tax credits to speed the transition to electric vehicles. The EV tax credits are now designated as the Clean Vehicle Credit, which lowers the EV cost with:

$3,750 tax credits for critical mining requirements;

$3,750 tax credits for battery component requirements; and,

$7,500 tax credits for critical mineral and battery component requirements.

The result? Mining companies are racing to extract more lithium supply to meet EV battery demand. As a result, these companies are lining up permits to open new lithium mines in the US, the European Union (EU), and Australia. For example, Anthony Tse of investment firm Franklin Templeton estimates that “real [lithium] supply [requirement will be] somewhere between 150,000 to 200,000 tonnes every single year. That's bigger than the whole market was 12 years ago.”

But mining activities are falling short of EV sales projections. Opening new mines requires years of permitting approvals, which will delay companies' ability to ramp up production. With the slower response of building new mines, The Boston Consulting Group (BCG) expects lithium supply to fall short of demand starting in 2030.

Even assuming that all the new lithium-mining projects that the industry currently regards as probable or possible go into operation, as well as a significant expansion of lithium-recycling projects, lithium supply in 2030 is expected to fall around 4% short of projected demand, or by around 100,000 metric tons of lithium carbonate equivalent (the processed form of raw lithium). (See Exhibit 1.) By 2035, that supply gap is projected to be acute—at least 1.1 million metric tons, or 24% less than demand. — Boston Consulting Group

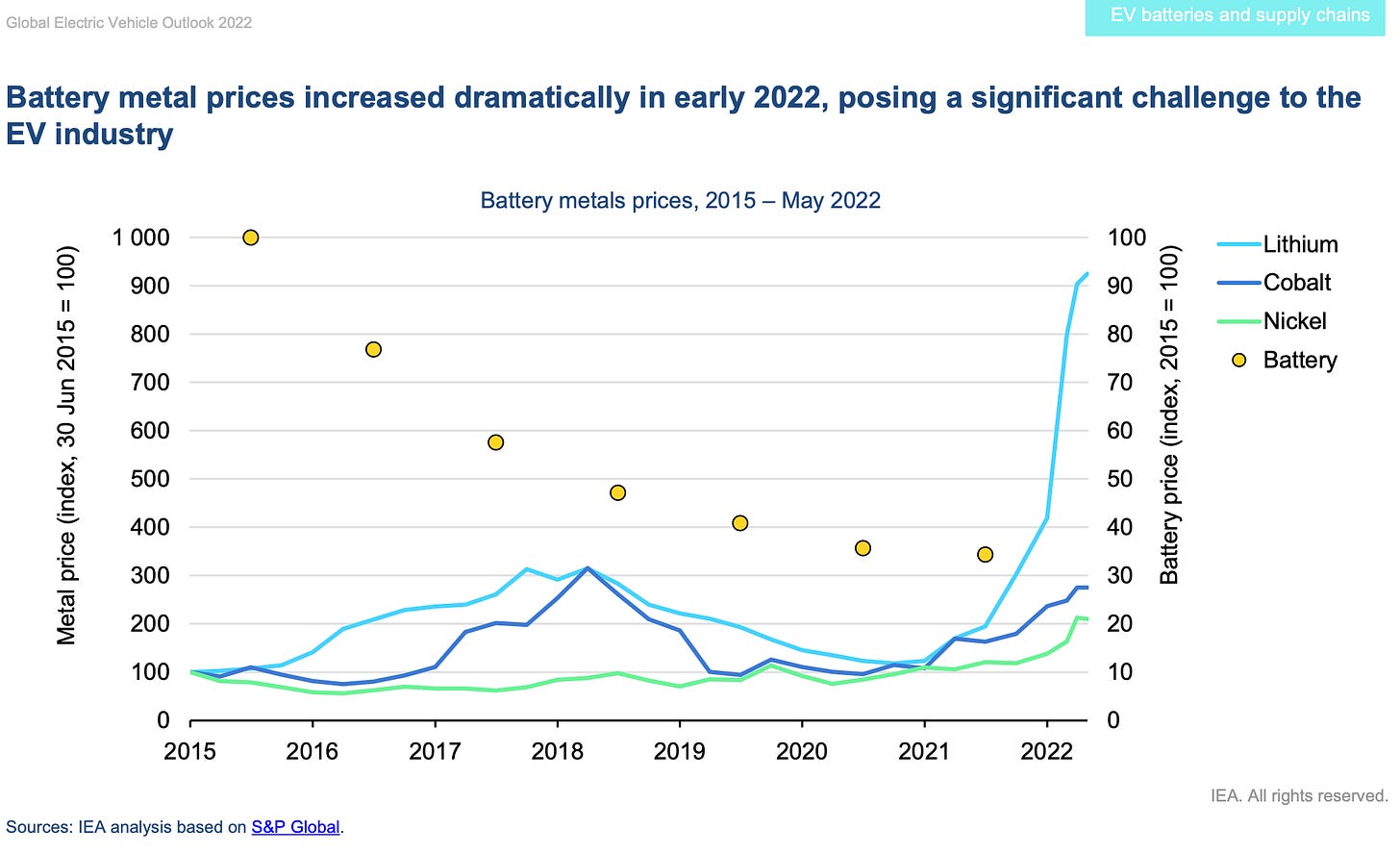

A short-term supply crunch has caused a 700% lithium price spike. According to the International Energy Agency (IEA), “In May 2022, lithium prices were over seven times higher than at the start of 2021.” The higher metal prices for lithium, cobalt, and nickel are now causing EV car battery prices to rise. BloombergNEF’s annual lithium-ion battery price survey shows a 7% increase in average pack prices in 2022 in real terms, the first increase in the survey's history, which, they assert, could "derail the arrival of affordable EVs.”

Companies are announcing sodium as an option.

Why use sodium instead of lithium to build batteries?

Sodium (Na) is readily available and distributed around the globe.

Sodium is the most common alkali metal and the sixth most abundant element on Earth, comprising 2.8 percent of Earth’s crust. It occurs abundantly in nature in compounds, especially common salt—sodium chloride (NaCl)—which forms the mineral halite and constitutes about 80 percent of the dissolved constituents of seawater. - Encyclopedia Britanica

Conversely, lithium, cobalt, and nickel, the main ingredients in high-energy-density lithium batteries, are mined exclusively in only a few countries. For example, the top four countries producing lithium are Australia, Chile, China, and Argentina. And over 70% of the world's cobalt production comes from one country, the Democratic Republic of the Congo.

Rising lithium and related metals costs have cut battery company profits. For example, Contemporary Amperex Technology Co. Ltd. (CATL), which has a 35% share of the global battery market, saw its net income fall 24% for Q1 2022 and its profit fall 41% due to sharply rising nickel and lithium prices.

Sodium frees battery manufacturers like CATL from worrying about commodity supply shortages and price spikes.

But can battery companies switch chemistries?

The lithium-ion supply chain is well-established, with, for example, more than 120 companies coordinating to supply Tesla. Switching battery shape and chemistry ripples through the supply chain as companies must change purchase contracts, manufacturing tooling, product design engineering, and product testing. Also, given the consumer safety testing requirements for cars and trucks, any significant change will take global coordination to meet regulatory approvals.

Yet the EV industry is already planning fundamental battery changes. Electric vehicle companies continue to adjust battery chemistries and invest in R&D for future chemistries, such as solid-state lithium-ion batteries. For example, Volkswagen is testing QuantumScape's solid-state batteries for its future vehicles.

Additionally, 42% of EVs will switch to lithium iron phosphate (LFP) by 2023. A rapid change was noticed early in 2022. "Tesla confirmed that nearly half of all its vehicles produced [in the first quarter of 2022] are already using cobalt-free iron-phosphate (LFP) batteries." In addition to the Model 3 and Model Y manufactured in China, Tesla will switch the Model 3 in Freemont, TX, to LFP. Electrek also reports that Tesla Gigafactory Berlin will incorporate China's BYD flat-blade, iron-phosphate battery technology — a change from the 4680 cylindrical batteries favored by Tesla. Expect that motivated companies will and can change their battery chemistry.

The switch to sodium-ion batteries is underway: Natron, CATL, BYD, HiNa

Why change? As reported by Bloomberg, “On paper, the cost of materials for these batteries is about 30% lower than the lithium-ion variety. There’s no risk of fire, either. They charge fast and have longer life cycles.”

Due to their advantages, the IEA forecasts that "sodium-ion batteries [could] reach market maturity by 2030, helping to reduce [battery] costs."

Four companies have recently been active with press announcements and industry articles on sodium-ion product launches, possibly speeding up the manufacturing timetable to bring products to market.

Natron Energy

Natron Energy is going into production with its sodium-ion batteries in the Clarios International manufacturing plant in Michigan in early 2023. Natron plans a 600 MW battery capacity to serve recent and planned customer contracts. Natron already manufactures a rack-mounted battery tray for data centers. Natron’s technical product brochure is available on its website.

The company plans to serve four markets that do not require high-power densities, such as computer data centers, industrial mobility (such as fork-lift trucks), EV fast chargers, and telecom applications (backup power for 5G networks).

The company claims 10x faster charging-discharging and an over 50,000 [charge-discharge] cycle life, making it ideal for industrial applications. In addition, the company claims its batteries have “no risk of thermal runaway or explosion under any conditions.”

Natron builds its batteries from two common materials, sodium for the electrolyte and Prussian blue, a widely used pigment, for the anode and cathode. These materials are readily available at stable prices.

The company is gaining commercial success, including:

Sales channel partnerships with eight companies, including ABB, CE+T Power, and Fuji-Bridex.[Source: Natron Energy’s website]

Sales contract for up to 13,500 sodium-ion batteries for the Vast 50 megawatt (MW) Solar 2 project in Mount Isa, Australia. [Source: Business Wire]

A strategic equity investment by United Airlines (UA) to electrify its ground operations. “UA has more than 12,000 pieces of motorized ground equipment, including tractors and gate operations, and only about a third of that fleet today is electrified.” [Source: Energy-Storage News]

CATL

Contemporary Amperex Technology Co., Ltd (CATL), the largest battery company and a Tesla supplier in China, announced its first generation sodium-ion battery last year.

CATL’s first generation of sodium-ion batteries has the advantages of high-energy density, fast-charging capability, excellent thermal stability, great low-temperature performance and high-integration efficiency, among others. The energy density of CATL’s sodium-ion battery cell can achieve up to 160Wh/kg, and the battery can charge in 15 minutes to 80% SOC at room temperature. Moreover, in a low-temperature environment of -20°C, the sodium-ion battery has a capacity retention rate of more than 90%, and its system integration efficiency can reach more than 80%.

The company is also planning to boost the power output to 200Wh/kg, which moves its density closer to the lithium battery when it introduces its 2nd generation battery.

CATL also plans to mix and match the sodium-ion and lithium-ion batteries, thus optimizing the advantages of each battery’s chemistries. In addition, the company also plans to use its Battery Management System (BMS) software to optimize the different mixes of the two battery types.

Unfortunately, CATL 2023 production is in doubt. Anjani Trivedi of Bloomberg reports that some supply-chain manufacturers are doubtful that the CATL batteries will be ready in 2023. She believes that “without hard work, we’re not going to see cheaper batteries or EVs, but a heap of fantastical ideas and a lot of money gone to waste.”

BYD

BYD Co. Ltd (“Build Your Dreams) manufactures batteries and EVs, so it is the only company that can fast-track sodium-ion batteries into cars. By September 2022, BYD sold nearly 2.68 million “new energy” passenger cars worldwide. Warren Buffet’s Berkshire Hathaway was an early company investor in 2008. In the first 11 months of 2022, BYD doubled its car production to 800,000 EVs, approaching Tesla’s 10-month volume of 908,573 deliveries.

BYDs sodium-ion plans for 2023 are shrouded in rumors. Newsletters that track the Chinese press report rumors that BYD will make a sodium-ion blade battery for its economy-priced cars in China, such as the Qin, Dolphin, and Seagull models.

HiNa

HiNa Battery Technology Co. Ltd. HiNa Battery began initial 1 GWh capacity battery production on November 29, 2022. The company plans to boost output by 3-5 GWh next year. The battery cells have 145 Wh/kg energy density with 4,500 charge-discharge cycles. In addition, HiNa is reported to install its battery technology in microgrids.

In June 2021, HiNa Battery Technology Co., Ltd., in collaboration with the Chinese Academy of Sciences (IOP-CAS), installed a 1 MWh sodium-ion battery (NIB)-based solar energy storage and intelligent micro-grid system in Taiyuan, China. The micro-grid system uses sodium-ion batteries as its main energy storage component and combines grid electricity, solar cells, and charging stations.

My take

Electric car sales growth is limited by the availability of low-cost batteries, not consumer demand.

For EV sales to take off, car models and inventories must increase to serve the price-sensitive consumer who needs an inexpensive car for city driving, job commuting, and shopping.

But to build these lower-priced cars, high-priced lithium, nickel, and cobalt chemistries must be replaced by sodium-ion battery chemistries. Reaching economy buyers with mass-produced sodium-ion batteries offers a chance for manufacturers to redirect limited battery metals to high-end cars and trucks, thus helping to meet demand in vehicles like the Ford 150 Lightning.

Will investors bring their money to build out the sodium-ion supply chain? Yes, global capital always moves fast to take advantage of business opportunities. So if companies like CATL and BYD develop the products, investors will want to fund the new growth market.

In addition, the sodium-ion technology will continuously improve. For example, Research labs in the US, EU, and China are rapidly working to discover new ways to improve the energy density of the batteries, just as they did with lithium batteries.

Although there is uncertainty about whether major companies like CATL and BYD will begin production in 2023, if one company breaks out of the pack, the others will race to catch up.

Recent science laboratory advances

The following press announcements highlight new directions in sodium-ion research.

Longer-lasting sodium-ion batteries are on the horizon. Pacific Northwest National Laboratory’s research team published their results on June 16, 2022. “The new PNNL-developed sodium-ion technology uses a naturally fire-extinguishing solution that is also impervious to temperature changes and can operate at high voltages” “In laboratory tests, the new design proved durable, holding 90 percent of its cell capacity after 300 cycles at 4.2 V, which is higher than most sodium-ion batteries previously reported.” [Source: Pacific Northwest National Laboratory (PNNL)]

Battery made of aluminum, sulfur, and salt proves fast, safe and low-cost. The Massachusetts Institute of Technology (MIT) team published the results on August 24, 2022. “…the MIT team set out to design a new type of battery out of readily available, inexpensive materials. … they settled on aluminum for one electrode and sulfur for the other, topped off with an electrolyte of molten chloro-aluminate salt. Not only are all of these ingredients cheap and common, but they’re not flammable, so there’s no risk of fire or explosion.” A startup company, Avanti, is commercializing the technology. [Source: New Atlas]

The cheap sodium-sulfur battery boasts 4x the capacity of lithium-ion. The international research team first published its findings on October 29, 2022. “Our [molton] sodium[-sulfur] battery has the potential to dramatically reduce costs while providing four times as much storage capacity [compared to standard lithium-ion batteries],” said Dr. Shenlong Zhao from the University of Sydney. [Source: New Atlas]

To learn about Cleantech Adoption services, go to: https://www.cleantechadoption.com